The news from the U.S. Patent and Trademark Office came in the form of an old-fashioned letter. We have received, it said, your application for a patent on a device to measure knee laxity.

That letter, says Professor Sandra Shultz, represented a monumental step.

“All the pieces are coming together,” she says. “That’s two years of work right there. If you had ever told me I was going to be doing this, I would have thought you were crazy.”

Knee laxity is a measure of motion in the human knee, critical in diagnosing joint and ligament health. Shultz, a co-director of UNCG’s Applied Neuromechanics Research Laboratory, is a scientist, more familiar with the body’s skeleton and musculature than the intricacies of product development and commercialization.

But luckily for Shultz and Professor Randy Schmitz, her collaborator and lab co-director, UNCG has people and mechanisms in place to help faculty, staff, and students navigate the labyrinth of research-based entrepreneurship.

It’s called LaunchUNCG.

The goal, says LaunchUNCG Director Justin Streuli, is to provide “white-glove service to help achieve a commercially viable product.”

In 2020, that’s a broader, more nuanced concept than what once was simply called technology transfer. Today, white-glove service might mean facilitating preliminary research to confirm that a market exists for a new product. It might include aid in securing funds for product development, networking in the business world, or engineering advice.

Whatever assistance may be needed, LaunchUNCG has on-campus connections or an external network to provide it.

LaunchUNCG is a critical driver to further UNC Greensboro’s strategic goal of student, regional, and knowledge transformation, says Dr. Terri L. Shelton, vice chancellor for research and engagement. “It’s about fostering a culture of innovation and enhancing the impact of our research.”

An important piece of that culture is a recent partnership between UNC Greensboro and NC A&T State University, and the National Science Foundation’s Innovation Corps program, better known as I-Corps.

Facilitated by LaunchUNCG, the Greensboro I-Corps site guides select students, faculty, and alumni of UNCG and NC A&T through an entrepreneurial bootcamp, encouraging them to perform market research early when their innovations are still at a nascent stage.

Early market research allows intellectual property developers to determine whether they have properly identified their intended customer base. Research team members interview prospective customers for feedback on their innovation’s design and functionality, including its physical features and benefits.

LaunchUNCG program manager Sam Seyedin describes I-Corps as a “go/no-go test.”

UNCG in 2019

3 newly granted patents

4 innovations licensed for commercial development

83% increase in innovation disclosures

50% increase in patent and trademark applications

AN ELECTRIFYING IDEA

Imagine cleansing wastewater of a harmful yet valuable element while, at the same time, helping to satisfy the world’s growing demand for high-performance batteries.

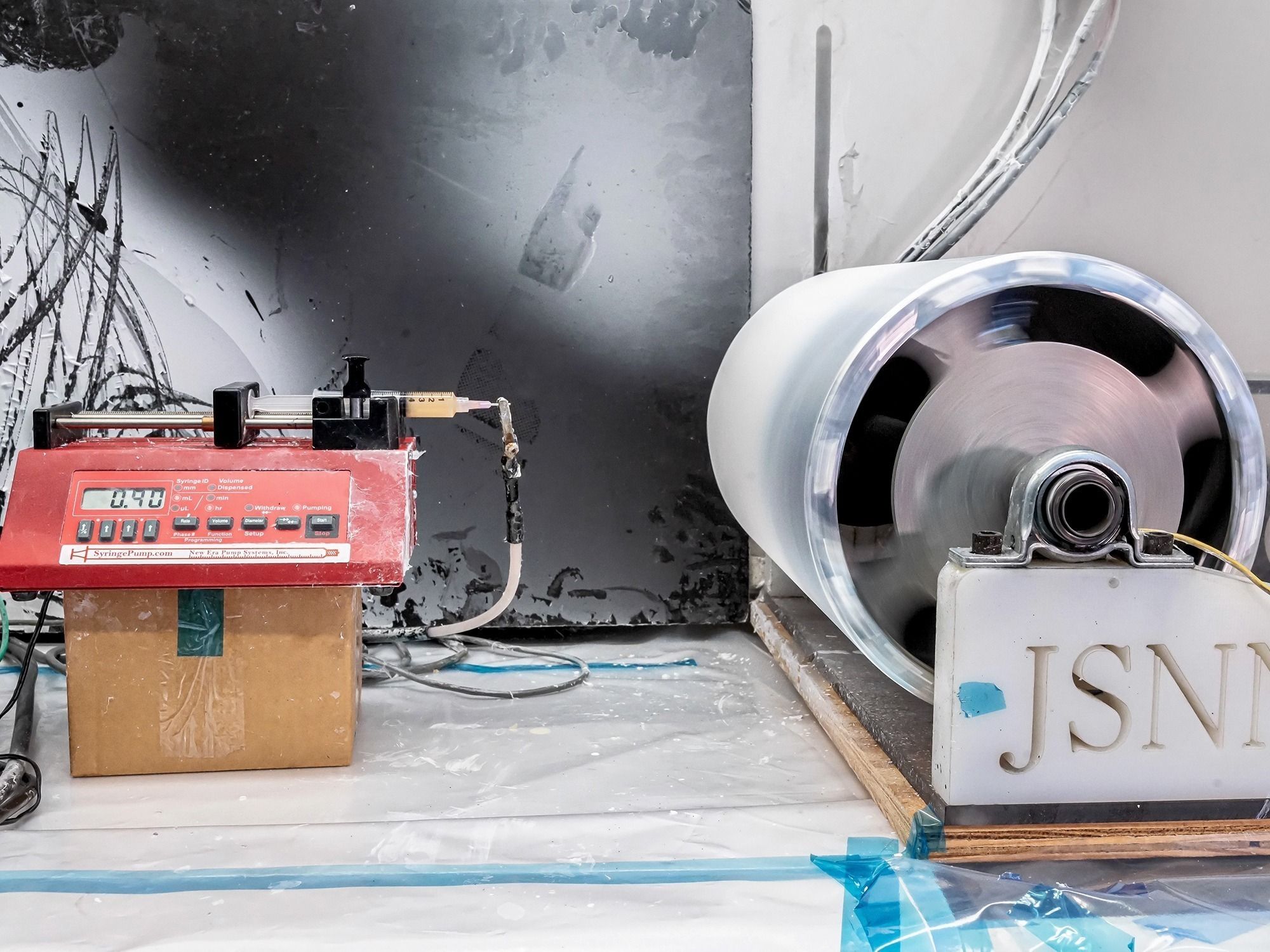

Transformative research at the Joint School of Nanoscience and Nanoengineering, or JSNN, promises to do just that. The project is led by Associate Professor Hemali Rathnayake, assisted by graduate student Sheeba Dawood.

The element lithium is in great demand as a primary component in long-lasting batteries that power everything from smartphones to Tesla electric vehicles.

“There is a huge market for lithium for energy storage applications,” Rathnayake says. Demand is so high that the light-colored substance has been called “white gold.”

The world’s largest lithium deposits are in Australia, with other large concentrations in South America. Yet trace amounts of lithium are quite common, especially in wastewater that is a byproduct of extracting petroleum from the earth.

The traditional method of removing this lightweight metal from petroleum wastewater utilizes evaporating settling ponds, a process that can take up to two years. And that’s just stage one of the reclamation process. Then, dried, settled material must be separated and refined to be of use.

Rathnayake and Dawood have devised a new way to remove lithium from petroleum wastewater – a lithium-trapping filter derived from a renewable resource. This proprietary nanomaterial is able to trap molecules of lithium measuring only one to three nanometers, or about a billionth of a meter.

The Greensboro I-Corps program, and then a $50,000 national I-Corps Award, supported Dawood as she conducted field research in the U.S. petroleum industry, including attending a trade show where she was able to access representatives of many companies.

The researchers determined that their filter can be commercially viable when the lithium content in water is 400 milligrams per liter or greater. Dawood learned that amounts of suspended lithium in wastewater range from 400 to 1500 milligrams per liter. The filtering process is faster and more efficient than the evaporative method, able to process up to 55 gallons per minute.

Another advantage of the nano-filter process, Rathnayake says, is that the polymer used to create the filter is naturally abundant, renewable, and therefore relatively inexpensive.

The petroleum industry, always looking for ways to trim costs and boost profits, has shown much interest in the filter, Dawood says, especially in Pennsylvania, North Dakota, and Arkansas. Those states mandate that petroleum production wastewater must be cleansed to remove environmentally harmful material.

Nationally, Dawood said, the petroleum industry annually produces 700 billion barrels of wastewater.

Like the gold dust that attracted prospectors to California in 1849, harvesting minute amounts of lithium can turn into real profits. It doesn’t take long to understand why these researchers are excited about their innovation’s potential.

Dawood, a scientist with an entrepreneur’s passion, hopes to create a company that will license the process and take it to market. She’s also identified firms that she might partner with to achieve the same end.

There’s another fascinating aspect to this nanotech innovation: The polymer that makes up the filter is a conductor. Once packed with lithium particles, the filters essentially become batteries, ready to store electricity.

Rathnayake and Dawood have trademarked a brand name for their nascent product, a name that pays homage to UNCG. It will be called Minerva Lithium.TM

Lithium can cost from $5,000 to $10,000 per ton, depending on the source. Mining rock-like lithium carbonate is the most expensive way to attain the metal. Above, Rathnayake and Dawood (left) hold a sample of their proprietary filter, woven at the JSNN using an electrospinning technique. With a lab-created saltwater sample, researchers demonstrate the power of their lithium-trapping method in the time-lapse photo series at the top of this section.

New UNCG patents in 2019

“Non-Aromatic Difluoro Analogues of Resorcylic Acid Lactones”

Inventors: Mitchell Croatt, Nicholas Oberlies, Lara Fakhouri, and Cedric Pearce

New class of chemical compounds, derived from a natural fungal compound, with potential applications in the treatment of carcinomas, leukemia, and other cancers.

“Virtual Reality Training to Enhance Locomotor Rehabilitation”

Inventor: Chris Rhea

A VR method to rehabilitate patients who have difficult walking as a result of illness or injury. Can serve a wide variety of populations with potential for use by patients in their own homes.

“Methods and Compositions for Inducing Hygienic Behavior in Honey Bees”

Inventors: Olav Rueppell and Kaira Wagoner

Nontoxic methods to improve removal of dead or disease brood among honeybees, to curb the devastating impacts of parasitic mite Varroa destructor on colonies and, ultimately, the agriculture industry and food security.

ADVANCING INNOVATION

LaunchUNCG helped qualify UNCG and NC A&T to become an I-Corps Site in 2017, a status achieved by only three other campuses in the UNC System. As an I-Corps Site, the universities received a five-year, $500,000 grant from the NSF.

With that funding, LaunchUNCG facilitates the training of multiple cohorts of innovators each year. As part of the training, cohort members receive funds to cover field research travel expenses. Depending on the product and intended market, research might be accomplished within a limited area, such as the Carolinas or Southeast. Other projects might send researchers farther afield.

The I-Corps funds required may be only a few thousand dollars. But those funds can make a critical, money-saving difference in the long run, especially for graduate students, professors, and recent alumni.

“A thousand bucks can go a long way for somebody who doesn’t have anything,” Streuli says.

I-Corps grant funds can also support building product prototypes, but only after extensive market and design research. Streuli requires at least 30 field interviews with potential customers before considering a prototype grant request.

Researchers with promising innovations that require further development may also apply to the national-level I-Corps program for more training and funds.

Closer to home, LaunchUNCG offers additional avenues of support. Streuli has allied the Greensboro I-Corps site with two state organizations dedicated to fostering entrepreneurs – NC IDEA, a private foundation supporting entrepreneurial endeavors with high-growth potential, and First Flight Venture Center, a non-profit business incubator focused on high-tech companies.

One of First Flight’s programs, called LiftOff, provides assistance and consulting to neophyte companies to help them navigate the early stages of developing their business.

Participation in the LiftOff program costs $5,000, which can be a stretch – or impossible – for an early-stage company. Thanks to a grant from NC IDEA, each year LaunchUNCG may send one team of entrepreneurs to take part in LiftOff. So can each of the other I-Corps Site campuses in North Carolina.

Successfully completing LiftOff gives teams a leg up in applying for top-level National Science Foundation grants from the Small Business Innovation Research, or SBIR, program. Seed funding awards of up to $1.75 million are available, with no equity stake required.

“My goal,” Streuli says, “is for LaunchUNCG startups to get SBIR grants.”

GREENSBORO I-CORPS

$1.2M development and startup funding

16 companies launched

56 teams

76 graduate and undergraduate students trained

75% minority-led

68% female-led

EVERY MINUTE MATTERS

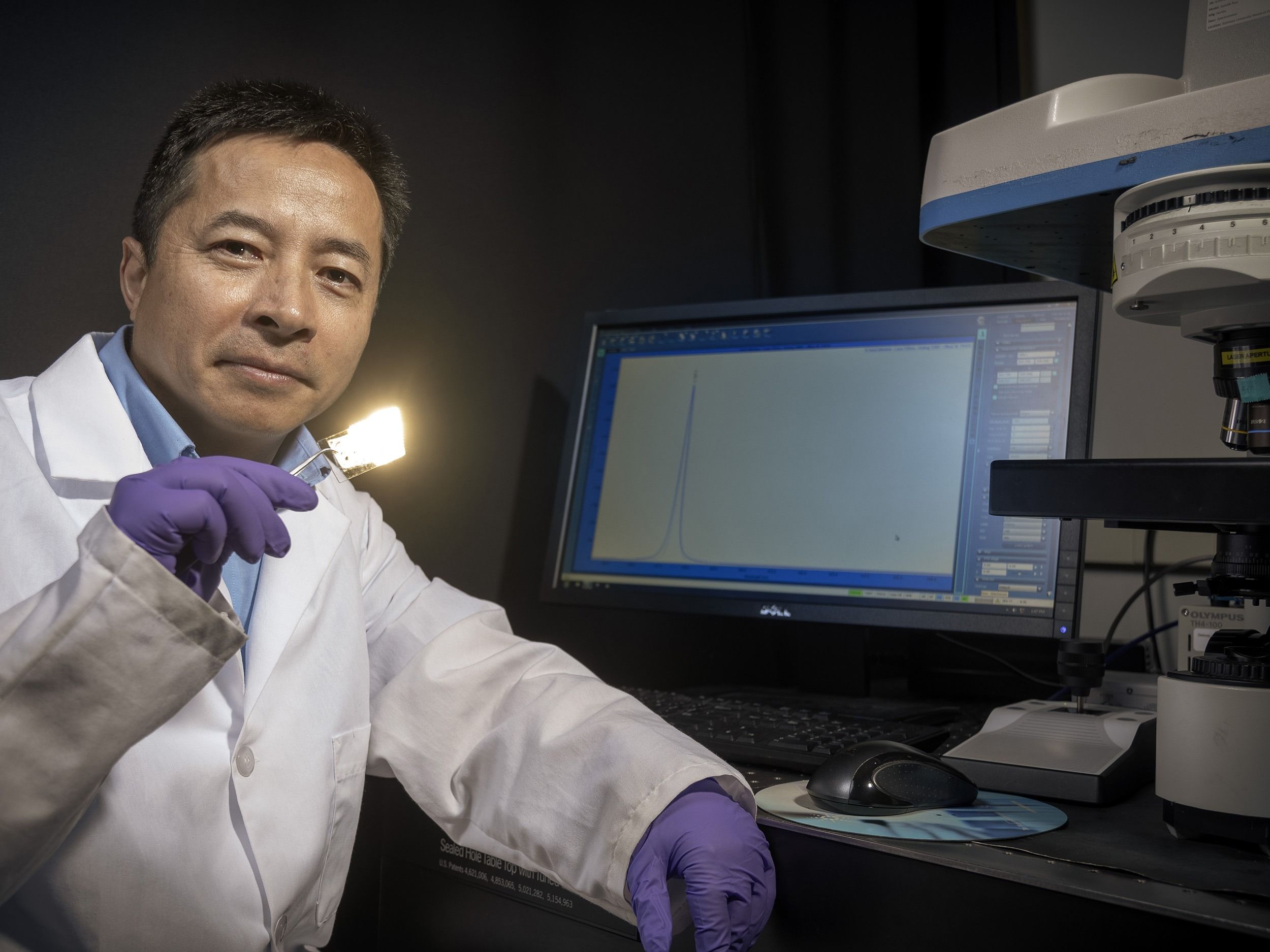

A UNCG I-Corps team recently received a $225,000 NSF SBIR grant and a $75,000 NC Biotechnology Center Technology Enhancement Grant in support of their device to detect heart attacks more quickly and accurately. After completing training with the first Greensboro cohort in 2017, Dr. Jianjun Wei (left) and Dr. Taylor Mabe (far right) also won a $50,000 grant to participate in the national I-Corps program, where they received a “Spirit of I-Corps Award” for their efforts.

Entrepreneurial Education

Creating a culture of innovation requires more than supporting researchers on campus who already have big ideas, says Streuli.

Through NC Entrepreneurship Center events, LaunchUNCG reaches out to get the entire campus and community thinking like entrepreneurs.

UNCG ENTREPRENEUR DAY

The annual event, now in its tenth year, matches over 90 classes across campus with guest lecturers from the business and nonprofit sectors, impacting over 2,000 students in a single day.

2 MINUTES TO WIN IT

The annual idea pitch competition gives 20 finalists from colleges across the Triad the opportunity to win over $2,000 in cash prizes, plus coworking memberships, business consultations, and more.

JERRY MCGUIRE STUDENT ENTREPRENEUR OF THE YEAR AWARD

The $1,000 annual scholarship supports UNCG’s most entrepreneurial student or team.

UNCG + FORGE MAKERSHIP

An annual scholarship winner receives a membership to Greensboro’s makerspace The Forge, to work on prototypes for their product idea.

FOCUSED ON THE KNEE

Much of Professor Shultz’s career research has focused on what may be humanity’s most problematic joint, the knee. Of specific interest to Shultz – and to many trainers, therapists, and physicians – is the condition of the knee’s ligaments.

The amount of ligament looseness, known as knee laxity, is an indicator of joint health. “When force is applied to the tibia – the lower leg bone,” Shultz explains, “knee laxity dictates how much it moves relative to the femur, or thigh bone.”

Knee laxity in young women has been of particular interest to Shultz and other researchers. Too much knee laxity, the kinesiologist says, “is a pretty strong predictor of future knee injury in young athletic females.” In older adults, greater knee laxity increases the risk of – and can also be caused by – osteoarthritis.

Most investigation of knee laxity is accomplished by manipulating the knee by hand. Mastering the process requires significant training and practice, and each diagnosis of knee laxity is highly subjective. The amount of laxity detected determines the treatment regimen prescribed, which may involve exercise, a brace, or perhaps surgery to tighten ligaments.

Devices to measure knee laxity exist, but current instruments measure only one range of motion. The knee, however, has three axes of motion.

Shultz and Schmitz saw need for a device that could accurately measure all aspects of knee laxity. They envisioned a device that would not require intensive training to use. It would be sized to fit on a training table and be light enough for a trainer or medical technician to set up and use. The device would mechanically manipulate the lower leg and measure all three axes of motion.

Profit, Shultz says, was not a motivating factor. The real drivers were a passion for research and knee joint health.

“This was something we needed,” she says. “We needed to continue to advance the research. And then we realized that this has big commercial potential.”

Guided in their quest by LaunchUNCG, the researchers located talent and resources on campus to assist in developing a prototype.

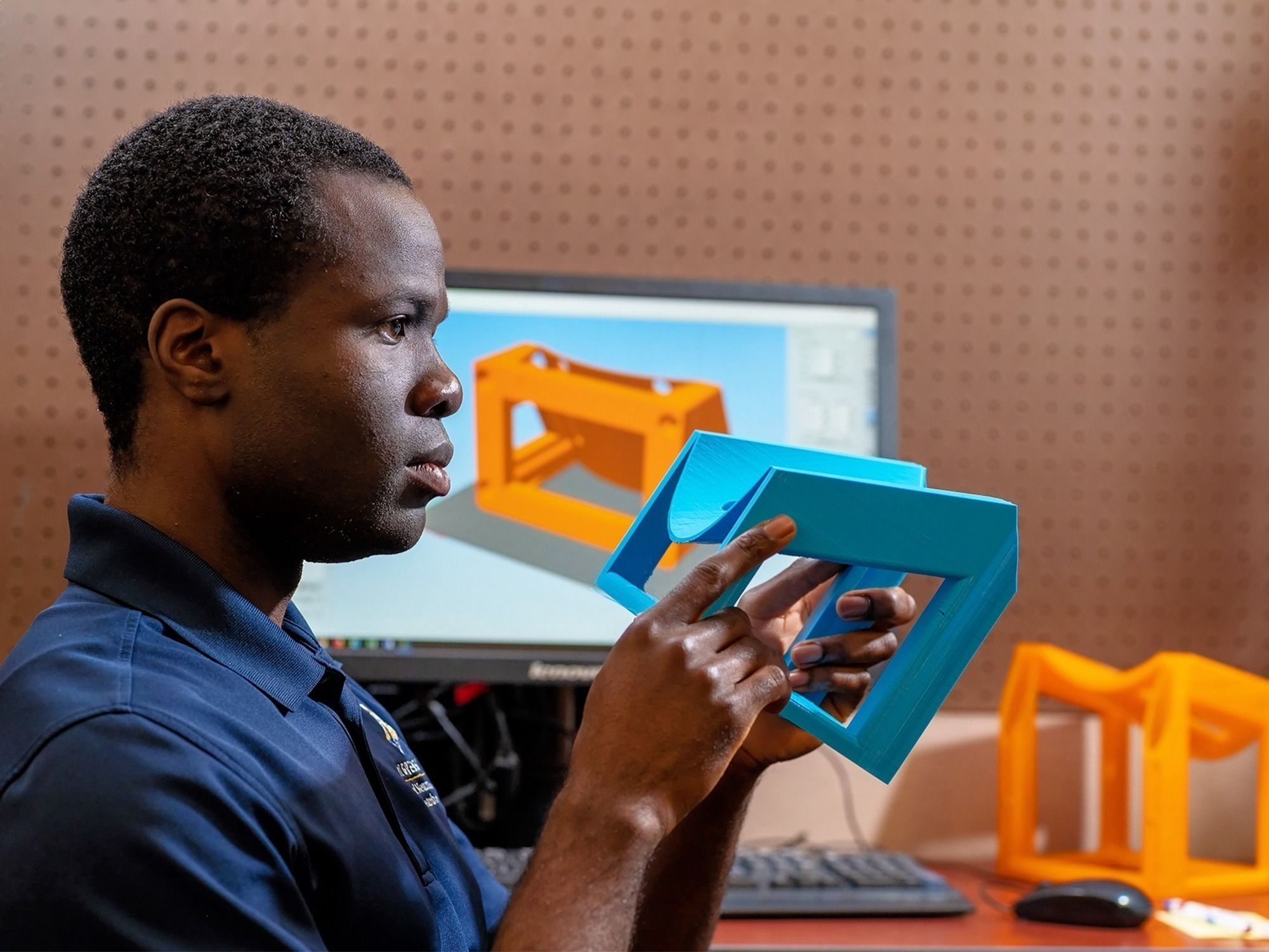

Through the I-Corps program, kinesiology graduate student Elvis Foli conducted field research across the Southeast. He interviewed trainers and physicians for their perspectives on improving knee laxity diagnoses. The information Foli gathered confirmed demand for the device.

Shultz and her team knew what the device needed to accomplish, but the team lacked the engineering expertise necessary to pull off a prototype. This time LaunchUNCG had the expertise in-house. Program manager Seyedin has a background in aeronautics. His engineering expertise cost the team of kinesiologists nothing.

Other campus resources helped the team further minimize costs. Then-kinesiology graduate student James Coppock collaborated with UNCG Libraries, employing their Fusion400 3D printer to create a complex component for the device. Printing the part took more than 36 hours. Not to mention all of the design work leading up to that final step.

Internal UNCG Giant Steps seed funding and a $100,000 NC Biotechnology Center grant are currently supporting the team as they continue to develop the prototype.

It was a decade ago when Shultz and Schmitz first kicked around the idea for a knee laxity diagnostic tool. But they were scientists first, not businesspeople. Without a fertile environment to nurture it, their idea lay dormant.

The development of LaunchUNCG, which created a “one-stop shop” to access all the resources available to academicians turned entrepreneurs, breathed new life into their idea.

With UNCG’s expanding resources in place to help move transformative ideas toward commercialization, the researchers are energized.

“We want to keep people healthy,” Shultz said. “We want to keep people physically active. That’s the goal of what we do in the lab.”

In the top photo, Schmitz, Seyedin, and Shultz discuss next steps for their prototype. In the next photo, graduate student Elvis Foli makes final adjustments to device components created with the university’s 3D printer. This type of printing was a first for UNCG Libraries, according to Digital Media Commons head Dr. Armondo Collins.