Cleaning Contaminated Water

Biochar, a centuries-old technology for enriching depleted agricultural soils, has been getting a second look in recent years as a solution to new challenges: making fire-resistant building materials, storing carbon from the atmosphere, and at UNCG, removing toxins from water.

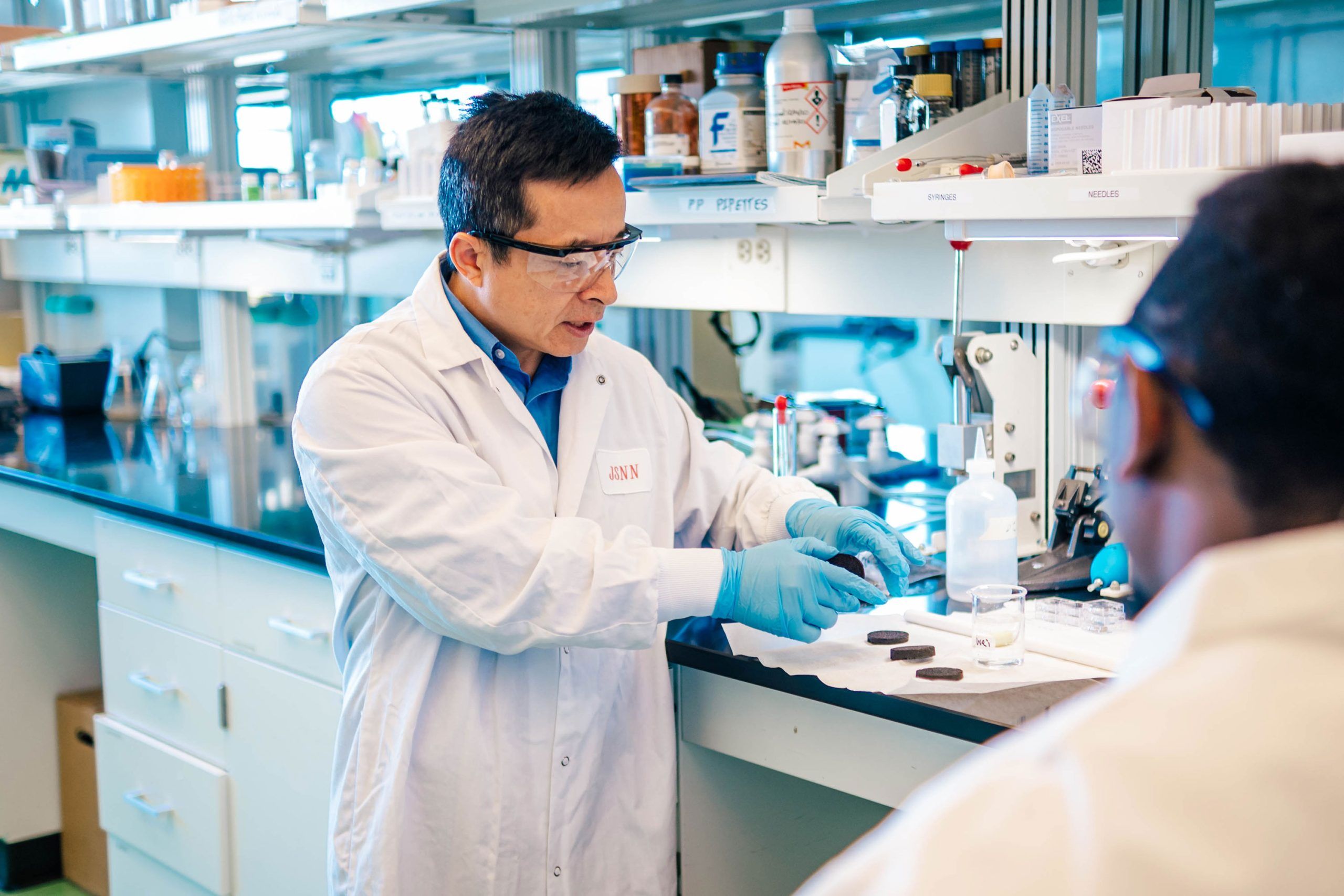

Dr. Jianjun Wei is researching ways to optimize biochar to remove lead, mercury, and other heavy metals, plus emergent chemicals known as PFAS, from water.

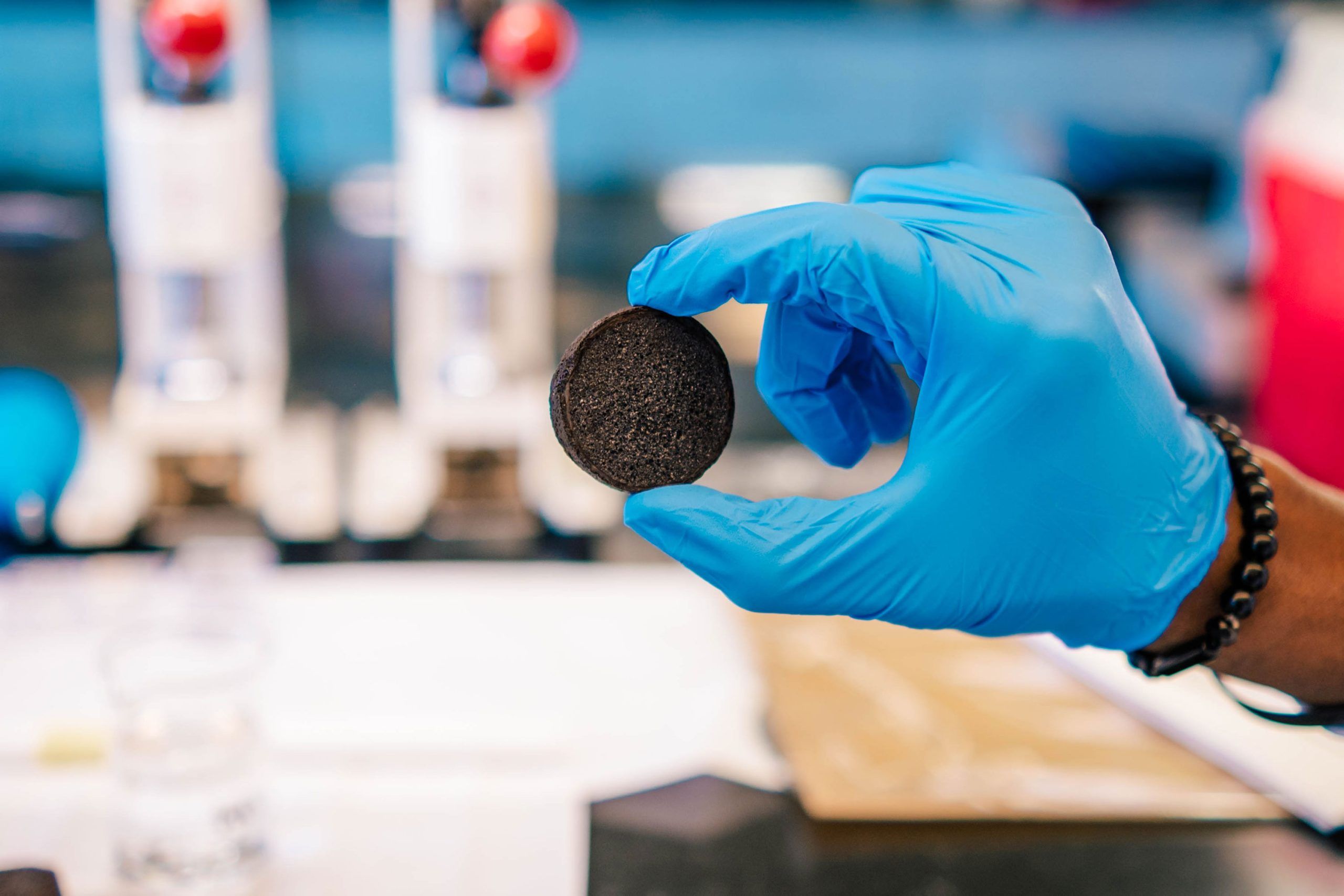

“Biochar” is a porous charcoal made from carbon-based materials, or biomass. It’s made by burning organic waste – such as sawdust, agricultural residues, and manure – in low-oxygen environments.

The Forest Service’s Forest Products Laboratory has been working over a decade to develop processes that produce biochar with different characteristics, the nanoscience professor and chemist says. They see biochar as a valuable use for massive woody residues left in forests after harvesting, wildfires, and insect and disease outbreaks.

With USDA funding, Wei and doctoral student Sherif Bukari are exploring how Forest Service biochar can best clean contaminated water.

Wei has a long history of carbon materials work. His research focuses on nanomaterials – ones so tiny they’re invisible to the unaided eye and hard to detect with conventional microscopy. Recently, he’s been studying ways to use such materials in environmental remediation. For example, he has explored ways to clean antibiotic-resistant bacteria from water and detect toxic organophosphates from pesticides.

Wei’s team alters the biochar so it binds better to toxic pollutants – specifically, heavy metal ions and chemicals known as PFAS.

“Training emerging scientists is a top priority in my research,” says Wei. Since leaving industry work for UNCG in 2013, he has mentored 26 doctoral students and four postdocs.

Wei’s work has been funded by the NSF, Department of Energy, NIH, NC Biotechnology Center, Department of Defense, and Syngenta, LLC.

Per- and polyfluoroalkyl substances, dubbed “forever chemicals” since they don’t break down in the human body or the environment, have been used in many products since the 1940s – including cosmetics, non-stick cookware, food packaging, and firefighting foams.

Recent studies have linked even low PFAS exposures to serious health effects. It’s long been known that heavy metals can be toxic, causing liver and kidney damage, cognitive impairment, cancer, and other ailments.

Heavy metal ions and PFAS are in very stable complexes and don’t biodegrade easily, making them tough to remove from water.

“Biochar is highly porous and has a large surface area, so there are many advantages to using it in the environment to remove contaminants,” Wei says. “But if we don’t modify the biochar, it doesn’t bind well to our targets.”

Wei’s team is working to increase that affinity, first by studying how heavy metal ions and PFAS interact with biochar with different surface modifications.

While other researchers have focused on powdered biochar, Wei reports biochar-based panels have advantages. Water would pass through the panels, leaving heavy metal ions or PFAS clinging to the surface. Once saturated, panels can be treated to remove contaminants and then reused, he says.

Wei is committed to using nanoscience to make the world better – particularly environmental quality. He points to statistics showing many U.S. water bodies are considered impaired and below EPA standards. These types of problems exist worldwide.

“We are hoping to commercialize this research, so that in the end, it has a big impact,” he says.